Quote:

Originally Posted by Flying

Not as of late. I've obtained a Ninja 300 flywheel and that is it. Currently focused clearing out work/life related tasks prior to me pulling the trigger on additional components and spending the time on the bike.

The next components to purchase are a new motorcycle stand and a Honda Rancher fuel pump, and even later down the line is stuff like coil-over-plugs, an Area P exhaust (which can be specified with an O2 bung, cool!), etc etc.

|

Cool.

Last week I ordered some Honda CBR600 COPs (Denso "shorties"), currently waiting for them to come in. I'll be wiring them up to a DIYAutotune Quadspark ignition module box (of course I'll only be using two of its four channels because the EX250 is only a two cylinder engine). The Microsquirt V3 only has "Logic Level" ignition outputs, which means they cannot be used to drive a coil directly so you have to use an ignition module. I know it sounds like a complex situation but it's judged to be a good solution, especially when you look at the real need to keep the electrical noise and interference isolated from the ECU as much as possible.

I have an Area P exhaust also, the long-ago-discontinued Pre-Gen model (so rare now it's Pre-Gen Unobtainium), it's such a great product (quality, performance, sound), without a doubt the best exhaust an EX250 could have. I cut and mounted an exhaust bung to it, the bung is located so the O2 sensor body takes up the narrow slot of space between the engine's oil pan and the linkage for the rear shock (I was very proud of how it turned out, perfectly measured and welded in).

Sometime during late February/early March I'll be installing an EX300 alternator rotor on my EX250. Because of this I've also ordered in a used stator cover off of Ebay and a couple of extra stator cover gaskets from a parts provider.

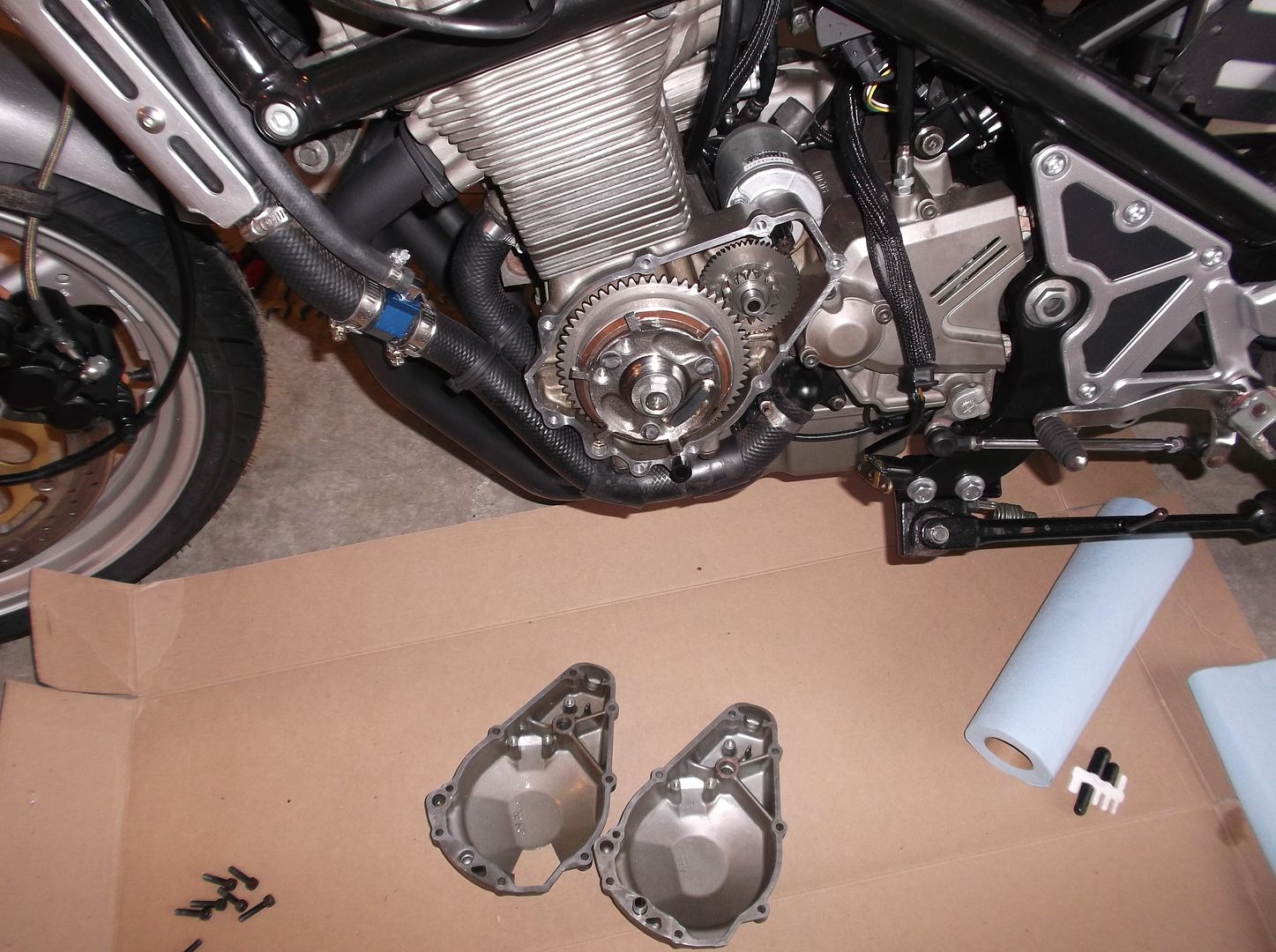

When I did the FI conversion on my Suzuki GSF400 (which included ignition control, which my original EX250 conversion did not) I discovered that I needed to be able to cut a viewing port into the engine cover on the left-hand side of the engine so I could set the initial basic timing angle (with my eyes and with a timing strobe light connected up to cylinder #1 spark plug). So I had to go to Ebay and purchase a used stator cover that I could cut (i.e. ruin). With this cut up cover installed on the bike I could refill the engine oil and run the engine while still being able to see inside where the engine timing was lining up, using the timing strobe light (yeah, the timing wheel still threw out a bit of oil during the run but I was able to get the job done).

The reason you have to do this is that the aftermarket ECU (the Microsquirt V3 in my project) doesn't automatically know where the Variable Reluctance Sensor ("VR sensor") is mounted within the engine's timing case, so the angular difference in degrees (out of 360 total) between the physical mounting place of the VR sensor and the exact "0" engine timing mark (Top-Dead-Center for cylinder #1) has to be determined visually and confirmed/adjusted with timing light testing.

The difference between the EX250 engine and the GSF400 engine is that the Rotor/Stator is on the opposite side of the engine on the GSF400, but the need to be able to see into the timing will probably be the same.

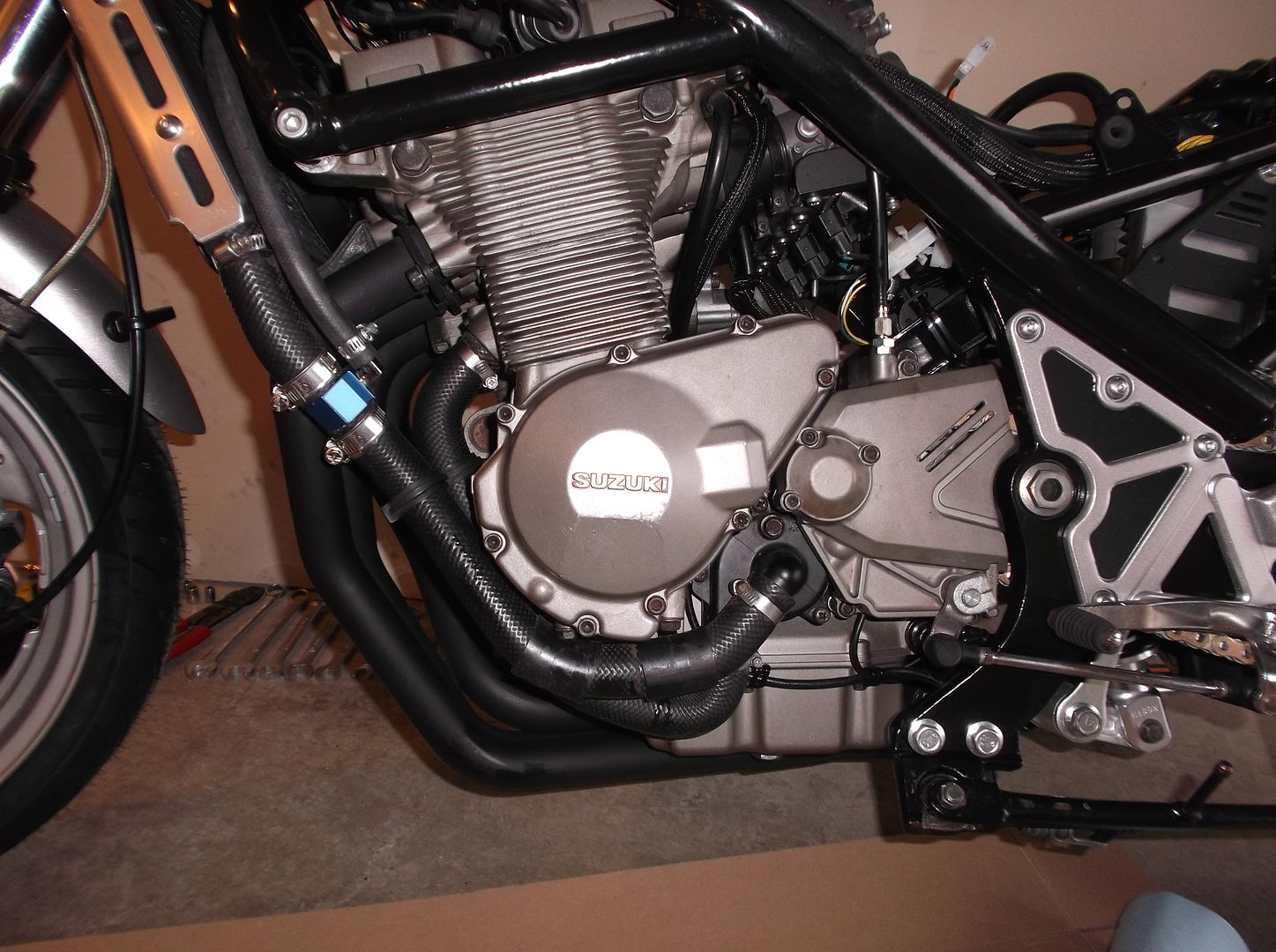

Here are a few pics of what it looked like when I was doing this work on the GSF400: