|

|

|

#1 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

Taking a Stab at Compression issues. 2007 250 ninja.

So, I've gone to ending the "oil in the coolant" thread since that was resolved with a new head gasket. But I wanted to share what was happening with that compression issue as promised. Sorry didn't get the audio recording, But I took the top off and opened a few things.

So here is where that stands. As far as timing goes I think it's spot on, but maybe I'm wrong. I took it apart on a whim tonight and Grabbed my cellphone to record it. I checked ALL the rocker arms to make sure they were coming down like they should. They are all seated right and push when the cams or whatever turn over. Open cover recording: https://youtu.be/TJN9HN3K4qE I set the clearance as close as I could to the middle of specs. They currently sit near. Inlets/Gas Side 0.20mm (0.0078 in.) Exhaust 0.24mm (0.0100 in.) at 2|T on the rotor, The Piston Closest to the throttle (right side) is fully raised. I used a wooden kabob stick to feel it coming up and down within the spark well. Now with all this being said, With everything put together the compression of each piston reports as follows. (engaged by the ingition.) Left side is Starter motor side; while right side is clutch side. Dry: Left = 45 psi, no spark plugs on either side. Left = 45 psi, with spark plug in right side. Right = 45 psi, no spark plugs on either side Right = 45 psi, with spark plug in left side. Wet (Few drops of oil): Left = 55 Psi, no spark plug on either side. Right = 55 Psi, no spark plug on either side. How does it ride you ask? It sounds like the explosions are happening on the inside of the engine and never escaping. Even though the engine is running it sounds like it's suffocating and barely coming out of the exhaust. I did not check this end of the muffler. Since it is an "h" tube it will be a deceiving result. The rpm's will reach 5k before maxing out and then Decreasing on it's own down to 4k. Maximum speed of 40 mph. (Scooters were giving me stink eyes while passing.) Piston rings may not be clocked right. Can't tell yet would need to take apart. but I figure improper clocking is unlikely since both pistons read the same compression. One should show worse than the other...Unless they are incorrectly clocked identically. And Finally, BONUS INFO! My compression test fitting (12mm for this bike's spark well.) Got stuck in the well because the dummies who made the kit set counter clock rotation to remove it. To get the fitting off after trying multiple things the most successful result was using blue loctite thread locker on the compression tester rubber tube, and twisting it into the thread of the adapter stuck in the spark well. (To be clear Don't ever put Loctite on the Actual spark well thread. I put it on the compression tester set only. between the rubber connector and the Interchangable adapter head piece.) I got it twisted pretty well, Left it for 24 hours. And counter clockwise twisted both pieces out pretty easily. Pro tip= Don't twist that in with two hands when you test it. Don't aim for snug; aim for attached, single hand tightened to the end with no torque added. Anyway I hope this intel Strikes a Eureka moment for someone. You guys have been so great, Spooph, Greg, Ghostt, motofool, but finding a mechanic in vegas who knows what they are doing or isn't lying through their teeth is literally impossible. Unfortunately You guys are my only real hope with this Damn nightmare. Thank you!  **Forgot to mention, Gas flow On Gray Line to carb is excellent. I don't know how to test the carb to the engine. :/ ** Last futzed with by f0r54ken; November 12th, 2015 at 05:22 AM. Reason: added note. |

|

|

|

|

|

#2 |

|

in your machine

Name: Scott

Location: Summer Shade, Ky.

Join Date: Oct 2014 Motorcycle(s): 98 Ninja 250/F12 aka ZX-2R "SERENITY", 91 Ninja 500/A5 aka ZX-5R "Phoenix", 84 Honda GL1200A "SIREN" Posts: A lot.

Blog Entries: 25

MOTM - Jun '17, May '16, Mar '15

|

The factory clearance specifications are .08 - .13mm (0.003-0.005 inches) for the intake valves and .11 - .16mm (0.004-0.006 inches) for the exhaust valves

__________________________________________________

violente et ignorantia ZX-2R BLOG Twitter and Instagram = Ghostt_Scott I'm not here to change your mind, just to inform.

|

|

|

1 out of 1 members found this post helpful. |

|

|

#3 |

|

-

Name: -

Location: -

Join Date: May 2009 Motorcycle(s): - Posts: A lot.

|

Are you working with a copy of the Kawasaki Ninja 250 Motorcycle Service Manual? It's full of interesting tidbits...

Example: the very first item under the heading "Compression Measurement" (on page 4-11) says "Thoroughly warm up the engine so that engine oil between the piston and cylinder wall will help seal compression as it does during normal running." The Service Manual cylinder compression range is 139 to 213 psi. I know that by the time people get around to trying to diagnose their engine's health with a compression test they often have the bike pretty well disassembled to the point that it won't/can't run, but it's important to know how the manufacturer meant the test to be carried out. And it's not just Kawasaki prescribing a warmed up engine for compression testing, every service manual I've ever read said to warm it up. |

|

|

|

|

|

#4 | |

|

-

Name: -

Location: -

Join Date: May 2009 Motorcycle(s): - Posts: A lot.

|

Quote:

Did somebody stuff something up your bike's exhausts? (I've read accounts of people finding their children's toys crammed into exhaust pipes) |

|

|

|

1 out of 1 members found this post helpful. |

|

|

#5 |

|

-

Name: -

Location: -

Join Date: May 2009 Motorcycle(s): - Posts: A lot.

|

watched your video, everything looks correct with the timing.

To better understand what you're seeing as you rotate the crankshaft it's important to remember that the camshafts are geared to move at 1/2 the rate of the crankshaft. So 720 degrees of crankshaft rotation = 360 degrees of camshaft rotation. Because the EX250 engine has a 180 degree "Flat Plane" type crankshaft the two pistons follow each other 180 degrees out of phase: 0 degrees crankshaft rotation = #1 cylinder TDC mark, spark plug fires 180 degrees crankshaft rotation = #2 cylinder TDC mark, spark plug fires ... then during the remaining 540 degrees of the four-stroke cycle the EX250's pistons are just carrying out the "housekeeping duties" of power stroke, exhaust stroke and intake stroke before finally getting back around to the money-shot moment of combustion. From your video: At 55 to 57 seconds on your video's timeline: Yes! You are definitely at "2T" (cylinder #2 top-dead-center, "TDC"). And, at this point in your video (55 to 57 seconds), not only is cylinder #2 at TDC but it is at the point in the 720 degree crankshaft cycle (four-stroke) where the spark plug is fired for combustion. You can tell because both of the camshaft lobes for #2 cylinder are off the tappet (not pressing it down to open the valve) and (bearing in mind the direction of camshaft rotation) you can see that the last valve that closed is the intake valve (it's pointed toward the rear of the bike which means it has a long way to go until it presses down on the tappet again). Your timing marks look to be perfect. Remember, the manual shows the timing marks pointing to the top of the cylinder head casting (the metal part only, their illustrations do not include the rubber gasket). Then, in the video, you turn the crankshaft 360 degrees (moving it from 180 degrees to 540 degrees into the 720 degree four-stroke cycle) to bring the 2T mark back into view again (2:33-2:48 on your video's timeline). Once again, everything looks just as it should at this point in the 720 degree four-stroke engine cycle. At this point the #2 cylinder has arrived back at TDC, just finishing its exhaust stroke. The #2 cylinder cam lobes are now facing each other which means the exhaust valve is just finishing closing and the intake valve is just beginning to open. This is called "valve overlap" and most engines have a small amount of it. |

|

|

1 out of 1 members found this post helpful. |

|

|

#6 |

|

-

Name: -

Location: -

Join Date: May 2009 Motorcycle(s): - Posts: A lot.

|

And... Ghost is right, you f-ed up the valve clearances.

Setting the valves this loose will have the effect of keeping them closed much longer than Kawasaki wants them to be because now it takes up a good bit of the cam lobe's lift profile just to close up the extra gap you've set on the tappet so there's less of the lobe's lift profile left to actuate the valves for the intake of air/fuel and the exhaust of gases. Could be part of that "suffocating" feeling you mentioned in your post. Less intake valve lift = less air/fuel mixture into the cylinder and less exhaust valve lift = reduced clearing of burned gasses (and no "scavenging" effect because there's no "valve overlap" between the intake and exhaust valves). You end up with the spark plug trying to fire a weak mixture of not much air/fuel combined with way too much old leftover exhaust gasses. And people on scooters go blowing past you. |

|

|

2 out of 2 members found this post helpful. |

|

|

#7 |

|

ninjette.org certified postwhore

Name: Spooph

Location: Golden, CO

Join Date: Jul 2010 Motorcycle(s): '08 Ninja 250R Posts: A lot.

MOTM - Oct '15

|

If setting the valve clearances doesn't change the out come, remove the head and do a leak-down test on it (obviously with the exhausts removed). If the head is still on the bike, you could always run it without the exhaust for a short while just to see if that has any affect on it...

Or you could remove the mufflers and push a wire or something down the headers to make sure they are clear of obstructions, but starting with the valves would be the best bet.

__________________________________________________

My therapist has 2 wheels and a seat. If you are ever in doubt to my tone, please refer to my avatar. |

|

|

1 out of 1 members found this post helpful. |

|

|

#8 | |

|

in your machine

Name: Scott

Location: Summer Shade, Ky.

Join Date: Oct 2014 Motorcycle(s): 98 Ninja 250/F12 aka ZX-2R "SERENITY", 91 Ninja 500/A5 aka ZX-5R "Phoenix", 84 Honda GL1200A "SIREN" Posts: A lot.

Blog Entries: 25

MOTM - Jun '17, May '16, Mar '15

|

Did you lap the head and cylinder surfaces? This is critical.

Here's a quick write-up Quote:

__________________________________________________

violente et ignorantia ZX-2R BLOG Twitter and Instagram = Ghostt_Scott I'm not here to change your mind, just to inform.

|

|

|

|

1 out of 1 members found this post helpful. |

|

|

#9 | |

|

Daily Ninjette rider

Name: Hernan

Location: Florida

Join Date: Mar 2011 Motorcycle(s): 2007 Ninja 250 Posts: A lot.

MOTY - 2016, MOTM - Dec '12, Jan '14, Jan '15, May '16

|

Quote:

For your 2007 engine, these are the acceptable valve-rocker's clearance ranges (only for dead cold condition of the engine): 0.08mm - 0.13mm for the intake valves 0.11mm - 0.16mm for the exhaust valves Those are just to compensate for the natural dilatation of the valves when the engine is hot. The working gaps become almost zero, erring on the loose side, so the valves actually close completely. The way you have those now, the breathing of the engine is diminished. Important caveat: http://n4mwd.blogspot.com/2013/06/ov...ts-during.html

__________________________________________________

Motofool  .................................Never ride faster than your guardian angel can fly "Mankind is composed of two sorts of men — those who love and create, and those who hate and destroy. Love is the bond between men, the way to teach and the center of the world." - José Martí |

|

|

|

|

|

|

#10 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

Thank you guys, This information is very helpful. You guys will be mad but I'm working with the evolution service manual (2008+) I figured it shouldn't have been that much different. Looks like I was wrong.

Ok, So I will set the rockers to proper spec. I know I had low compression a week after the head gasket went with the coolant issue. But Greg I think you're right. The exhaust sounds stuck. It was pretty rapid and I don't have any kids to stick toys in it. once I adjust the valves to proper spec If it still sounds like a fart in a marshmallow factory I'll take the exhaust off and clean the inside like toilet brush. Spooph, I plan on it I know the next step is a leak down test. Lemme ask too. is there a way I can check the valve stem integrity with just the cover off? I Could go down as far as removing the timing assembly too tonight. I'm avoiding taking the head apart again for now until I'm left with no other possibilities. Ghostt, Thank you for those measurements. I kind of wonder if there is anything Else I should know. I suppose I can just suck it up and buy the service manual. :/ Unless someone has a digital version they can email me? Does it say it can't be resold? Not sure how copyright works for books. f0r54ken@hotmail.com I did check the head for warping. I did not bore or lap any ends though just cleaned them well. I used a duct tape roll horizontally and pushed down around the cylinder section on the bottom of the head. then used the smallest feeler to check all around the roll for blips and chips. I repeated for both sides. Couldn't get the feeler to go between the roll and the bottom of the head. I hope I described that properly. I used a new gasket with some copper spray and got no leaks after running for 25 miles.  So that's good at least. So that's good at least.

|

|

|

|

|

|

#11 | |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

Quote:

I forgot to mention, Yes I was open throttle on all of the tests. I also did it Closed throttle. all tests resulted in 45 psi still. |

|

|

|

|

|

|

#12 |

|

in your machine

Name: Scott

Location: Summer Shade, Ky.

Join Date: Oct 2014 Motorcycle(s): 98 Ninja 250/F12 aka ZX-2R "SERENITY", 91 Ninja 500/A5 aka ZX-5R "Phoenix", 84 Honda GL1200A "SIREN" Posts: A lot.

Blog Entries: 25

MOTM - Jun '17, May '16, Mar '15

|

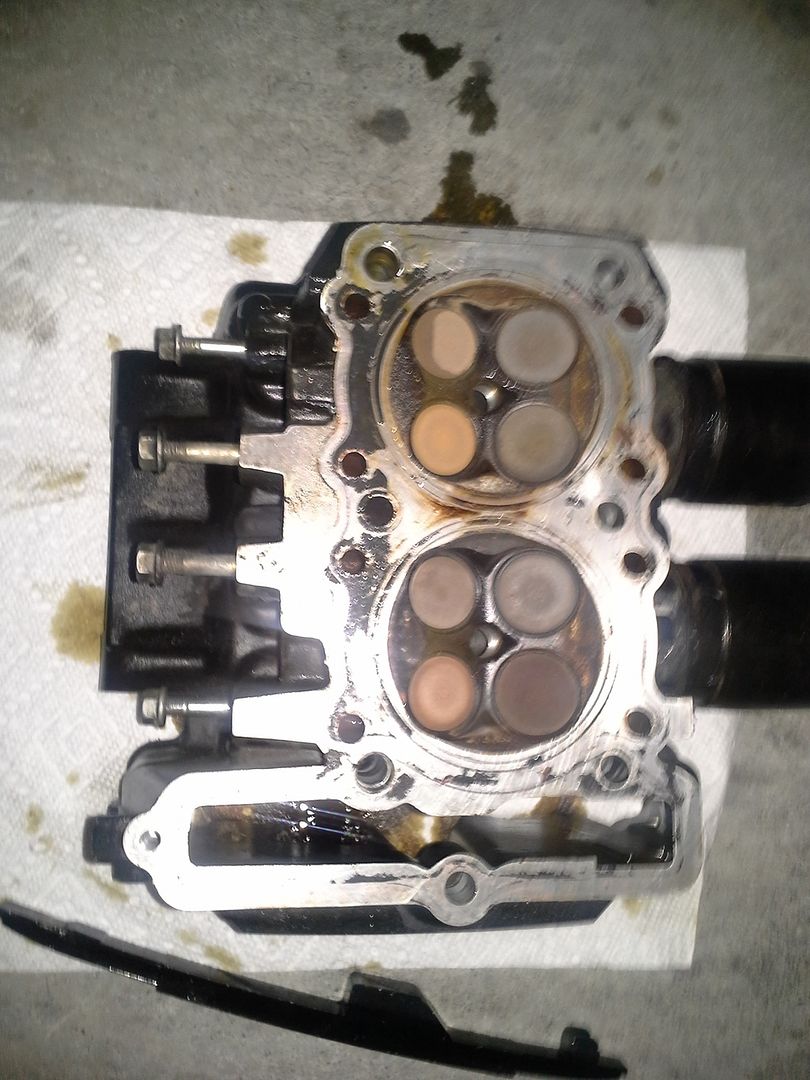

I forgot to attach the pictures, keep in mind these are of a EX500, NOT a Ninjette.

__________________________________________________

violente et ignorantia ZX-2R BLOG Twitter and Instagram = Ghostt_Scott I'm not here to change your mind, just to inform.

|

|

|

|

|

|

#13 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

|

|

|

|

|

|

#14 |

|

ninjette.org certified postwhore

Name: Spooph

Location: Golden, CO

Join Date: Jul 2010 Motorcycle(s): '08 Ninja 250R Posts: A lot.

MOTM - Oct '15

|

I'm not aware of any way to inspect the valve stems without removing them from the head, however, if you have the head off, it's not difficult to remove them - I presume you have a valve compressor tool?

Something like this: http://store.schnitzracing.com/schni...lGEaAvcq8P8HAQ

__________________________________________________

My therapist has 2 wheels and a seat. If you are ever in doubt to my tone, please refer to my avatar. |

|

|

1 out of 1 members found this post helpful. |

|

|

#15 | |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

Quote:

Hey when am I gonna beable to mark your guy's posts as helpful? No, I don't have that tool. I'm pretty sure they aren't bent though. I checked where they lay on the bottom of the head when it was off. nothing was extruding or depressing more than the others. ( I hear that is the main sign of bending.  Also, In my experience to get the valve to bend you'd have to pretty much stick a garden hose in your engine and fill it with. Short story, When I was riding through a storm with my car, I thought 8 inches of water running by the gutter wasn't so bad. I was wrong, With a low air intake, it sucked in a whole bunch of water and hydrolocked at 4k rpm. I miss the little guy :/ but yeah, I'd imagine bent valve stems should be pretty obvious. I'll be fixing the rocker height tonight. Hopefully I can fix the problems so I can spend time telling everyone how I did it instead of fixing a new one haha. |

|

|

|

|

|

|

#16 |

|

in your machine

Name: Scott

Location: Summer Shade, Ky.

Join Date: Oct 2014 Motorcycle(s): 98 Ninja 250/F12 aka ZX-2R "SERENITY", 91 Ninja 500/A5 aka ZX-5R "Phoenix", 84 Honda GL1200A "SIREN" Posts: A lot.

Blog Entries: 25

MOTM - Jun '17, May '16, Mar '15

|

Lapping is very important for proper gasket mating, and sealing.

__________________________________________________

violente et ignorantia ZX-2R BLOG Twitter and Instagram = Ghostt_Scott I'm not here to change your mind, just to inform.

|

|

|

1 out of 1 members found this post helpful. |

|

|

#17 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

I couldn't find this suggested in the manual. (Grabbed one during my lunch break from the library) Is this something for a higher mileage bike? mine's at about 9000.

Better yet, I don't want to assume a problem with the mating points, as much as I don't want to assume there isn't one. I did clean it very well and had no warping. So after I adjust the clearance. what can I do with what tools to actually narrow down this lack of sealing? I want to be positive that I need to remove the head before I remove the head again. |

|

|

|

|

|

#18 | |

|

in your machine

Name: Scott

Location: Summer Shade, Ky.

Join Date: Oct 2014 Motorcycle(s): 98 Ninja 250/F12 aka ZX-2R "SERENITY", 91 Ninja 500/A5 aka ZX-5R "Phoenix", 84 Honda GL1200A "SIREN" Posts: A lot.

Blog Entries: 25

MOTM - Jun '17, May '16, Mar '15

|

Quote:

It's just good engine building practice.

__________________________________________________

violente et ignorantia ZX-2R BLOG Twitter and Instagram = Ghostt_Scott I'm not here to change your mind, just to inform.

|

|

|

|

|

|

|

#19 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

God **** piece of mother ****ing horse **** b**** c*** a** mother ****er i can't believe it! The compression tester was broken! the brand. new. Compression tester! >

I hooked up the other one I bought that I was gonna return cause it didn't come with a 12mm fitting. But after doing the proper valve clearance and 2 hours I thought, Eh What the hell. The other compression tester Showed at least 140psi on C-2, but the battery is becoming exhausted. it's doing that Weeoh weeooohh weeeeeeoooohhh wind down. could only get the strength to 130 psi on C-1 I need to reassemble it and ride for a little to recharge it. Now I question compression test behavior. Just to make sure, I held the ignition down 4 seconds and the sequence went like this, "Roll - 30 psi - Roll - 65 psi - Roll - 90 Psi - Roll - 120 Psi - Roll - 140 Psi - Roll - 140psi - Roll - 140 psi." Same behavior on both sides. Argh! I'm gonna put this back together and we'll see how it feels and sounds. This is the best, worst news i've gotten all month. |

|

|

|

|

|

#20 |

|

in your machine

Name: Scott

Location: Summer Shade, Ky.

Join Date: Oct 2014 Motorcycle(s): 98 Ninja 250/F12 aka ZX-2R "SERENITY", 91 Ninja 500/A5 aka ZX-5R "Phoenix", 84 Honda GL1200A "SIREN" Posts: A lot.

Blog Entries: 25

MOTM - Jun '17, May '16, Mar '15

|

I'd say put it back together, and ride.

__________________________________________________

violente et ignorantia ZX-2R BLOG Twitter and Instagram = Ghostt_Scott I'm not here to change your mind, just to inform.

|

|

|

|

|

|

#21 |

|

ninjette.org certified postwhore

Name: Mark

Location: Portland

Join Date: Sep 2010 Motorcycle(s): Cheap Italian Suit. Otherwise known as Dew Kitty Posts: A lot.

|

For compression issues, I may or may not be wearing this. Be forewarned, it may cause other, and more concerning, 'issues'.

|

|

|

1 out of 1 members found this post helpful. |

|

|

#22 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

Argh...I give up guys. I'm tapping out. Replacing parts and taking apart ain't so bad. but mystery problems?...I got enough problems. lol

After being put together it no longer sounds like the combustion is stuck inside which is great. But the bike still runs like sh!t and I can't figure out why. valves are just right now for the feelers I used. and the engine got this occasional knock. on it's test ride. So I'm gonna go buy a brand new bike this weekend instead (Carter power sports said diagnosis is 114.00 and if they had to open up the engine it would be 1300.00 + parts. No thanks! We'll see in about a week. I'm gonna either part it out at a very fair price, Sell it for like $500 whole to a mechanic. I might keep it in the background and leisurely work on it. we'll see what comes first. |

|

|

|

|

|

#23 |

|

ninjette.org member

Name: steven

Location: new york

Join Date: Jun 2015 Motorcycle(s): 2004 kawasaki ninja 250 Posts: 44

|

just out of curiosity but how many miles on the motorcycle? thanks

|

|

|

|

|

|

#24 |

|

ninjette.org member

Name: Ash

Location: Las Vegas

Join Date: Sep 2015 Motorcycle(s): Kawasaki ninja ex250 2007 Posts: 85

|

|

|

|

1 out of 1 members found this post helpful. |

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| [Solved] Starter issues Ninja 250 (2007) | f0r54ken | 1986 - 2007 Ninja 250R Tech Talk | 47 | November 1st, 2015 01:33 PM |

| JE High Compression Piston Kit (13.5:1 compression, 356cc displacement) | Timpo | 2013 - 2017 Ninja 300 Tech Talk | 8 | October 12th, 2015 07:21 PM |

| Several Issues with 2007 Ninja | Paulgello | 1986 - 2007 Ninja 250R Tech Talk | 6 | May 17th, 2015 11:47 AM |

|

|