|

|

|

#1 |

|

All the news that's fit to excerpt

Name: newsie

Location: who knows?

Join Date: Jun 2008 Motorcycle(s): only digital replicas Posts: Too much.

|

[cycleworld.com] - The Power Stroke

How does burning of an aerosolized fuel mixture turn its potential energy to mechanical kinetic energy in a four-stroke engine?

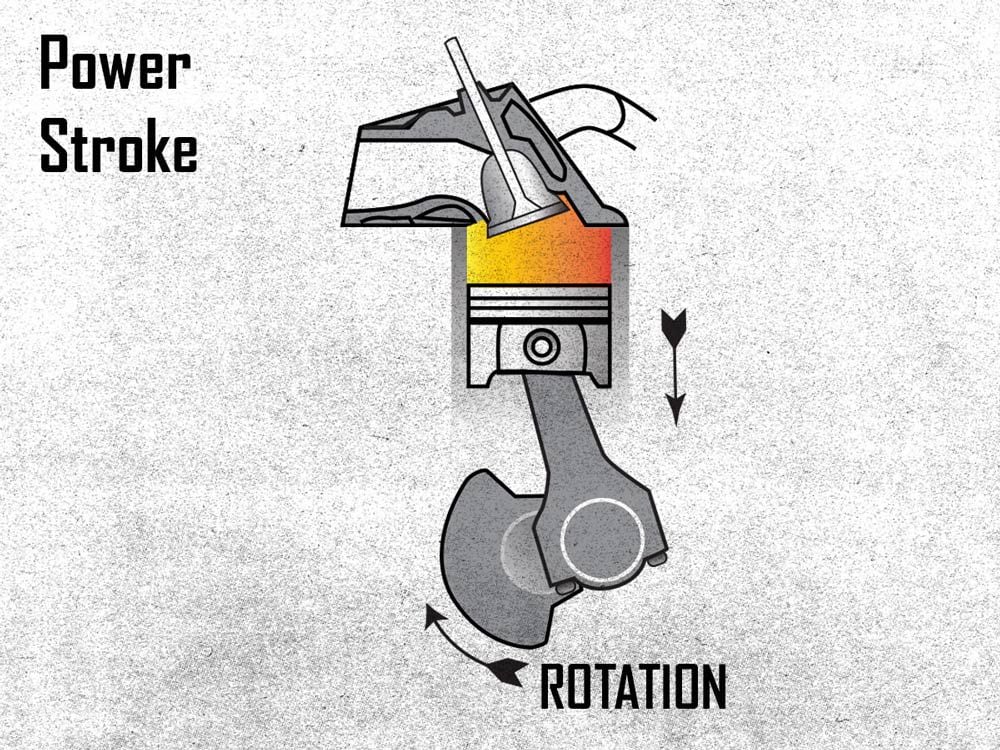

Click here to view on their site.  Kevin Cameron has been writing about motorcycles for nearly 50 years, first for Cycle magazine and, since 1992, for Cycle World. (Robert Martin/)The ignition spark begins the power stroke many degrees before top dead center (BTDC). This starts the process of releasing the chemical energy in the air-fuel mixture.* Molecular arrangements of higher energy are broken apart by heat (initially, that of the spark) so they can recombine into arrangements of lower energy. The difference is released in the form of greatly increased molecular velocities: heat. The temperature of the compressed mixture skyrockets, and its pressure is multiplied roughly seven times. This is the engine’s driving force. As you would expect, less than 100 percent of the fuel actually burns. Some is forced into piston ring crevice volume (1–2 percent) and some is so cooled by being close to cooler metal walls (called “quenching”) that it burns incompletely. Combustion efficiency is therefore somewhere in the high 90s. Engineers work hard to nudge this higher, because that reduces Unburned Hydrocarbon (UHC) emissions. In general, combustion persists ATDC for roughly as many degrees as ignition occurs BTDC. So if best torque occurs at 36 BTDC, the combustion period is roughly 36 x 2 = 72 degrees. In an engine having very slow combustion, such as Harley-Davidson’s first iron XR of 1970 (ignition at 50 BTDC) the whole combustion event could require 50 x 2 = 100 crankshaft degrees. Related: The Intake Stroke  Combustion continues ATDC for about as long as the spark fires BTDC. (Illustration by Robert Martin and Ralph Hermens/)When power stroke cylinder pressure is graphed out, we see that nothing much happens for several degrees after ignition. This is because the growth of the flame kernel is at first limited by its small area. Then pressure accelerates upward, reaching a peak value shortly after TDC. As the piston starts down on its power (expansion) stroke, cylinder pressure falls because the volume in which the hot combustion gas is confined increases rapidly. Although cylinder pressure is falling, the crankshaft lever arm on which it is acting is increasing. At TDC, torque on the crank is zero because the effective crank arm is zero, but as the crankpin is displaced laterally by crank rotation, the lever on which combustion gas pressure acts grows longer. Maximum moment, or torque on the crank, is reached at about 30 degrees ATDC. Very quickly, cylinder pressure drops to such a low value that it’s more valuable to begin the exhaust process early than it is to continue the expansion of such low-pressure combustion gas. About 80 percent of the pressure energy of combustion has been transferred to the piston by 80 ATDC. Correct ignition timing varies with engine design variables, and it varies with rpm and throttle opening in any given design. Functionally, it is that timing which reaches peak combustion pressure at about 11 degrees ATDC, which is roughly where the piston’s downward motion becomes significant. Because there is heat loss from combustion gas to piston crown and combustion chamber surfaces, best efficiency occurs with shorter rather than longer combustion. This is how Keith Duckworth’s classic Formula 1 engine—the Cosworth DFV—was able to show its heels to higher-revving V-12 engines with tremendously greater total valve area: DFV’s ignition timing for best torque was just 27 degrees. Not the 50 or even 60 degrees BTDC timings that had become typical in engines with deep hemi combustion chambers and tall piston domes. Why did those designs need such early ignition? The space between a tall piston dome and a deep combustion chamber is like the peel of half an orange—so thin that charge motion in it is quickly brought to rest as the piston nears TDC. There is no room in which charge motion can persist (and there may be deep valve clearance cutaways in the piston dome to act as turbulence stoppers). Aside from the long combustion, there was also the issue of surface area. The area of a deep hemi chamber with a 90-degree valve included angle is exactly twice that of the cylinder bore, and there is a similar increase in piston crown area when a tall dome is added. Heat loss in such engines not only continues for a long time (because of slow combustion), it also takes place through excessive surface area. I always think of Germany’s wartime MG42 machine gun, whose barrel, in heavy use, had to be exchanged for a fresh, cool one every 250 shots. Why? Because if it became any hotter, it could fire spontaneously, the hot barrel acting as an ignition source. In a piston engine, the analogy is that the extra heat entering those over-large piston and chamber surfaces abnormally increases their temperature—especially if the engine is air-cooled. The hot surfaces rapidly heat fresh charge in contact with them, accelerating the pre-flame chemical reactions that can end in detonation (I almost said “in tears”). To compensate, compression ratio in such “hot” engines must be lower, resulting in a loss of performance and fuel efficiency. Related: The Compression Stroke  Detention typically occurs near bottom dead center and around the edges of the cyclinder. This Kawasaki H2R 750cc triple piston died of detonation, destroying the top land and then moved onto ring lands. Eventually it seized. (Jeff Allen /)Remember that the words “detonation” and “preignition” describe different phenomena. In preignition, something very hot in the combustion chamber, usually an overheated spark plug electrode or glowing carbon deposits, ignites the mixture before the ignition spark. This typically occurs around bottom center, obliging the piston to compress a burning mixture. This so rapidly heats and weakens the piston that it fails almost immediately. Detonation, on the other hand, occurs at the very end of an otherwise normal combustion. Small volumes of “end-gas” (unburned mixture out at the cylinder wall) having been heated to some 950 degrees Fahrenheit by all the heat it has picked up, autoignites, then burns at or above the local speed of sound, generating shocks that damage parts. We hear this as “knock” or “tinkle.” Slow combustion also results in loss of what I will call “effective compression ratio.” Charge burning at TDC has the benefit of the full compression ratio, but charge burning long after TDC will be expanded less, resulting in its delivering less-than-maximum energy to the piston crown. Why does everything in life have to be so complicated?

__________________________________________________

I'm a bot. I don't need no stinkin' signature... |

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| [cycleworld.com] - The Compression Stroke | Ninjette Newsbot | Motorcycling News | 0 | December 21st, 2023 04:11 AM |

| [cycleworld.com] - The Intake Stroke | Ninjette Newsbot | Motorcycling News | 0 | December 12th, 2023 01:10 PM |

| [cycleworld.com] - The Four-Stroke and Its History Explained | Ninjette Newsbot | Motorcycling News | 0 | December 8th, 2023 03:24 PM |

| [cycleworld.com] - How the Two-Stroke Thing Got Going | Ninjette Newsbot | Motorcycling News | 0 | March 30th, 2023 04:41 PM |

| [visordown.com] - WATCH: Langen Two Stroke gets a full power Dyno run | Ninjette Newsbot | Motorcycling News | 0 | February 11th, 2021 05:00 AM |

|

|